Applications

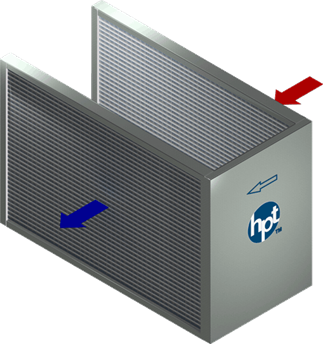

DHP Dehumidification Heat Pipes are wrap-around devices used in air conditioning systems to enhance dehumidification, reduce load on A/C equipment, and reduce or eliminate reheat. By precooling air before it reaches the cooling coil and reheating it afterward, these systems improve humidity control, reduce equipment load, and deliver dryer supply air.

Capabilities Overview

Coilmaster’s dehumidification heat pipes are passive, mechanical-free devices that enhance A/C performance using two modules. The first module precools entering air, reducing the burden on the cooling coil and lowering the air’s dew point and absolute humidity ratio. The second module reheats the air stream, producing dryer supply air and reducing relative humidity in occupied spaces to help prevent mold or mildew

Energy & Cost Savings

Since heat pipes use recovered heat from the entering air for reheat, active reheat for humidity control is minimized or eliminated. At the same time, precooling reduces load on the cooling coil, which allows you to reduce the size of the cooling coil, chilled water requirements, and ultimately energy costs.

Capacity Control

Valves can be installed on individual circuits and grouped in stages to turn them on or off according to demand, giving designers the flexibility to adjust capacity as ambient conditions change. This setup helps maintain efficient operation during part load while keeping performance consistent under peak load.