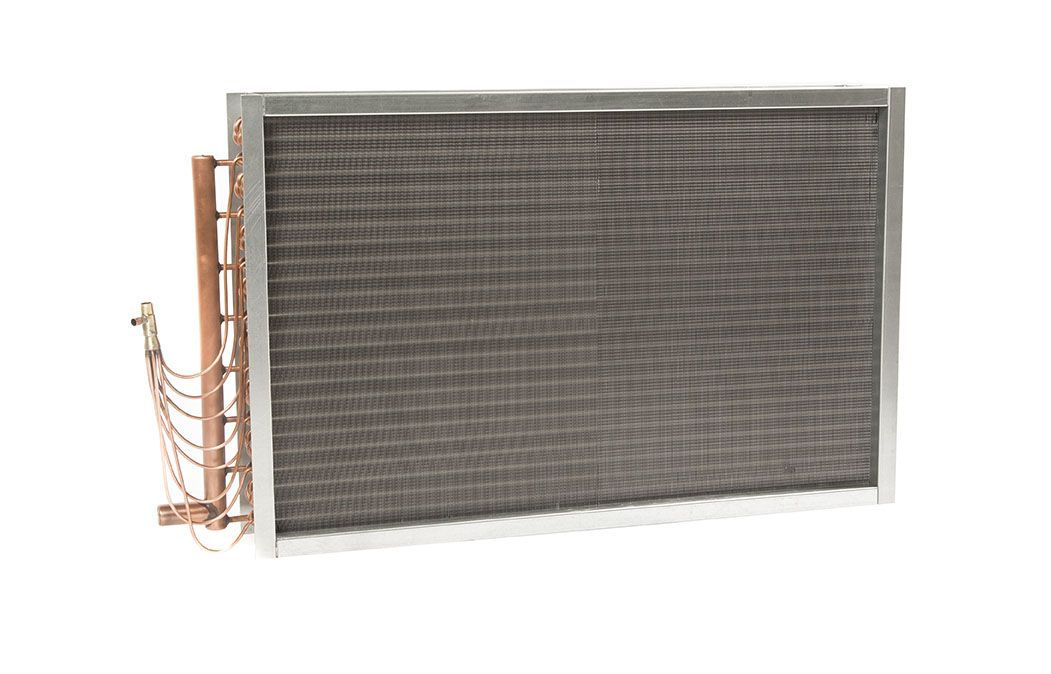

Applications

Designed for use in comfort cooling, process cooling, and refrigeration, Coilmaster evaporator coils are compatible with all modern refrigerants. Our proprietary circuiting ensures optimal system performance at minimal air-side and refrigerant pressure drops. A variety of load-split options provides the flexibility designers need to optimize the system at both design and part-load conditions. Coils are easily customized for hot-gas bypass or heat pump usage. Our pressurized method of shipping evaporator coils also gives you the assurance of leak-free operation. Our refrigerant coils have undergone the rigors of cycle testing for use with high-pressure R-410A refrigerant, and are safety listed with 750 psig rating.

Capabilities Overview

With a wide range of circuiting options and customizable features, Coilmaster evaporator coils can be configured to meet the specific demands of your system.

Single Circuit

These evaporator coils are most common with single compressor systems. They consist of only one refrigerant distributor and do not provide for variable loads. This is most commonly used in air-conditioning systems with constant airflow and space/return air temperature. Intertwined circuiting feeds refrigerant evenly across the coil face under part-load conditions. The coil retains up to 70% of the design capacity when one circuit is deactivated, as the entire fin surface provides cooling. The result is higher suction pressure , which allows compressors to operate more efficiently—making it an ideal solution for multi-zone and VAV units.

Four-Circuit Face Split Intertwined

This is the most flexible arrangement available on an evaporator. Depending on the number of compressors, piping arrangement and controls, this coil style can operate as an intertwined coil or a face split coil – all while accommodating four independent refrigerant circuits. This arrangement is commonly used in multi-zone and VAV units as well.

Traditional Face Split

At part load, only a portion of the coil face remains active. Suction pressure remains low in the active circuit, thus providing a lower fin temperature and leaving air temperature in the active portion of the face. Active circuits should always be the bottom section of the coil to prevent humidity spikes due to re-evaporation of condensate.

Traditional Row Split

Typically seen in six-row evaporators, this arrangement will feed the first four rows with one distributor and the last two rows with the other distributor to achieve a 50/50 load split. Due to the limited options for achieving a 50/50 split and the fact that the lower suction temperatures do not allow for higher efficiencies at part-load, this arrangement is less commonly used.

Refrigerant Distributors

Each refrigerant distributor is selected to optimally feed the evaporator coil for proper boil-off. Removable nozzles are installed at the factory to minimize installation and field maintenance. Venturi-type distributors are available for applications with wide variations in load. Distributors can be factory mounted for horizontal, upturn or downturn arrangement.

Optional Features

Auxiliary Side Connectors

As an option, auxiliary side connectors for use with hot gas bypass circuits can also be installed at the factory.

Equalizer Lines / TXV’s

Optionally, 1/4″ equalizer lines can be factory installed into the suction headers, facilitating installation of the thermostatic expansion valve (TXV). As a full value-added option, evaporator coils can be shipped with factory-installed thermostatic expansion valves.

Intermediate Drain Pans

Integral intermediate drain pans are available for installations requiring a single coil in lieu of multiple stacked coils. This feature provides for condensate removal from the upper section of the coil for installation as a single unit.

Product Drawing

Coilmaster Intertwined Evaporator Coil Assembly Drawing (75 KB)