Our manufacturing capabilities allow us to meet a wide range of system requirements for heat exchangers across HVAC, refrigeration, and industrial applications. With a full line of custom-configured coils and a streamlined production process, we deliver reliable, efficient solutions at scale. From fast-turn booster coils to complex, multi-circuited evaporators, we deliver high-efficiency solutions with fast, reliable lead times.

Booster Coils

Our line of Booster Coils for hot water or low-pressure steam heating applications are pre-engineered for fast turnaround and reliable performance.

Condenser Coils

Our condenser coils are custom-designed to reject heat efficiently across a wide range of refrigerant applications.

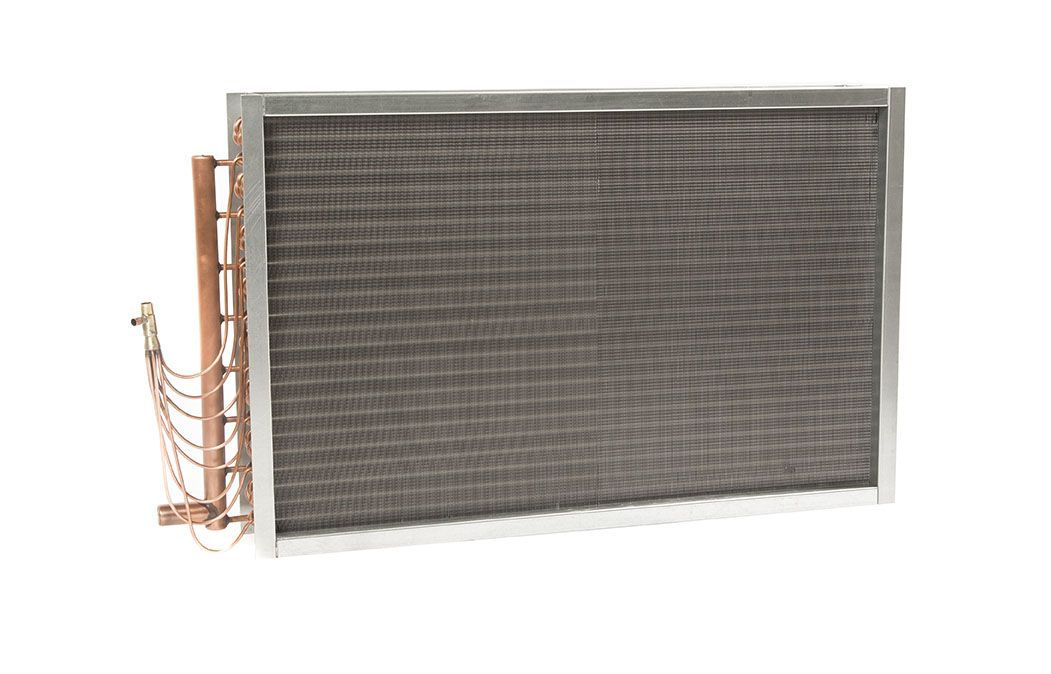

Evaporator Coils

Designed for use in comfort cooling, process cooling, and refrigeration, Coilmaster evaporator coils are proven for use with all of today’s refrigerants.

Fluid Coils

Coilmaster fluid coils are designed for air cooling or heating applications using chilled water, hot water or brine (e.g., ethylene or propylene glycol mixtures).

Insulated Cased Coils

Our insulated cased coils are the most cost effective option on the market for complete, ready-to-install assembly—ideal for reducing labor time and simplifying installation in the field.

Oval Tube Technology

Our revolutionary oval tube technology dramatically reduces air-side pressure drop, allowing a smaller fan motor to achieve the same cooling capacity – resulting in a significant reduction in energy usage and costs.

Refrigerated Case Coils

Specifically engineered for refrigerated display cases, these coils deliver reliable performance in food retail and commercial refrigeration environments.

Standard Steam Coils

An economical choice for general purpose or process heating, steam coils are the choice when inlet air temperatures will not fall below freezing.

Steam Distributing Coils

Due to their tube-within-tube design, steam distributing coils provide a level of protection against freezing in low-temp applications.

General Product Capabilities

Every Coilmaster coil is custom-configured for the job, with a wide selection of materials, coatings, and configurations to match your exact application requirements.

Coating options:

- Epoxy Polymer (E-Coat)

- Heresite

- Others available by request

| Tube Diameter | Tube Wall Width | Tube Stagger | Fin Corrugations | Fin Materials | FPI Range |

|---|---|---|---|---|---|

3/8" Tubes |

0.014"

0.022" |

1.00" x 0.866" | Sine Wave

Louvered |

0.0060" Aluminum

0.0075" Aluminum 0.0045" Copper |

8 to 22

|

| 3/8" Tubes | 0.014"

0.022" |

1.25" x 1.083" | Sine Wave | 0.0060" Aluminum

0.0075" Aluminum 0.0100" Aluminum 0.0060" Copper |

6 to 16 |

| 1/2" Tubes | 0.016"

0.025" |

1.25" x 1.083" | Sine Wave

V-Waffle Flat |

0.0060" Aluminum

0.0075" Aluminum 0.0100" Aluminum 0.0060" Copper |

6 to 16 |

| 5/8" Tubes | 0.020"

0.025" 0.035" 0.049" |

1.50" x 1.299" | Sine Wave

V-Waffle Flat |

0.0060" Aluminum

0.0075" Aluminum 0.0100" Aluminum 0.0060" Copper |

4 to 14 |

| 1.00" Tubes | 0.035"

0.049" |

3.00" x 2.125" | Sine Wave |

0.0075" Aluminum

0.0100" Aluminum 0.0075" Copper |

4 to 14 |