Applications

The SMART Water-Glycol Pump System is designed for projects where supply and exhaust air streams are too far apart for passive energy recovery. Ideal for distances greater than 200 feet or for facilities requiring two-season recovery, it provides reliable energy transfer regardless of air stream location.

Capabilities Overview

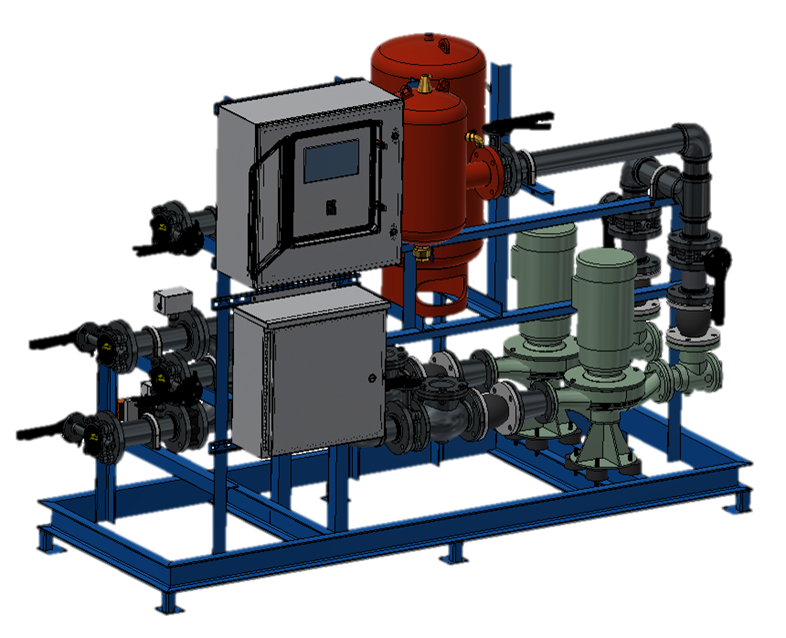

Coilmaster’s SMART Water-Glycol Pump System combines pump skid, coils, and air sensors into a fully integrated package that ships pre-engineered and factory-assembled. Installation requires contractors to pipe between coils and skid and wire the power supply, air sensors, and Building Management System (BMS). They also perform standard hydronic tasks including startup and installing insulation.

The system accommodates ethylene or propylene glycol mixtures, or water with corrosion inhibitors in warmer climates. It also outperforms most glycol systems, delivering sensible effectiveness greater than 50% on a six-row system at 500 FPM—meeting ASHRAE 90.1 Section 6.7.7.3 requirements for Laboratory Exhaust Systems.

Smart Controls

The system controller modulates valve positions and pump speeds to optimize performance in heating, cooling, economizer, and frost-control modes. A 10” touchscreen provides clear visualization of system operation for maintenance teams. For remote interfaces, the controller can communicate with your BMS via BACnet or Modbus and using MSTP or Ethernet. It can also operate independently with full automatic control.

Simple Selection Process

Designing a system is easy: provide airflow rates, design summer and winter conditions, unit geometries, desired supply conditions, and the distance between air streams. Our Applications Engineers will deliver an optimized selection.